Building on Decades of Industry Experience

ClearBakk, together with the five companies comprised of the ALSYS Group have completed over 550 water related projects. We bring nearly 35 years of industry experience and have worked on projects ranging from Produced Water Treatment, Mining Wastewater Treatment, Tailings Dewatering, Potable Water Treatment, Sewage Water Treatment, Polymer Hydration Plants, Biological Treatment, Laundry Wastewater, Oily Water, Oil Purification, Bilge Water, Industrial Wastewater, Caustic Degreaser Recovery, Metals Wastewater Treatment, Lithium Mining Wastewater, Feasibility Studies, and Custom Designed Equipment.

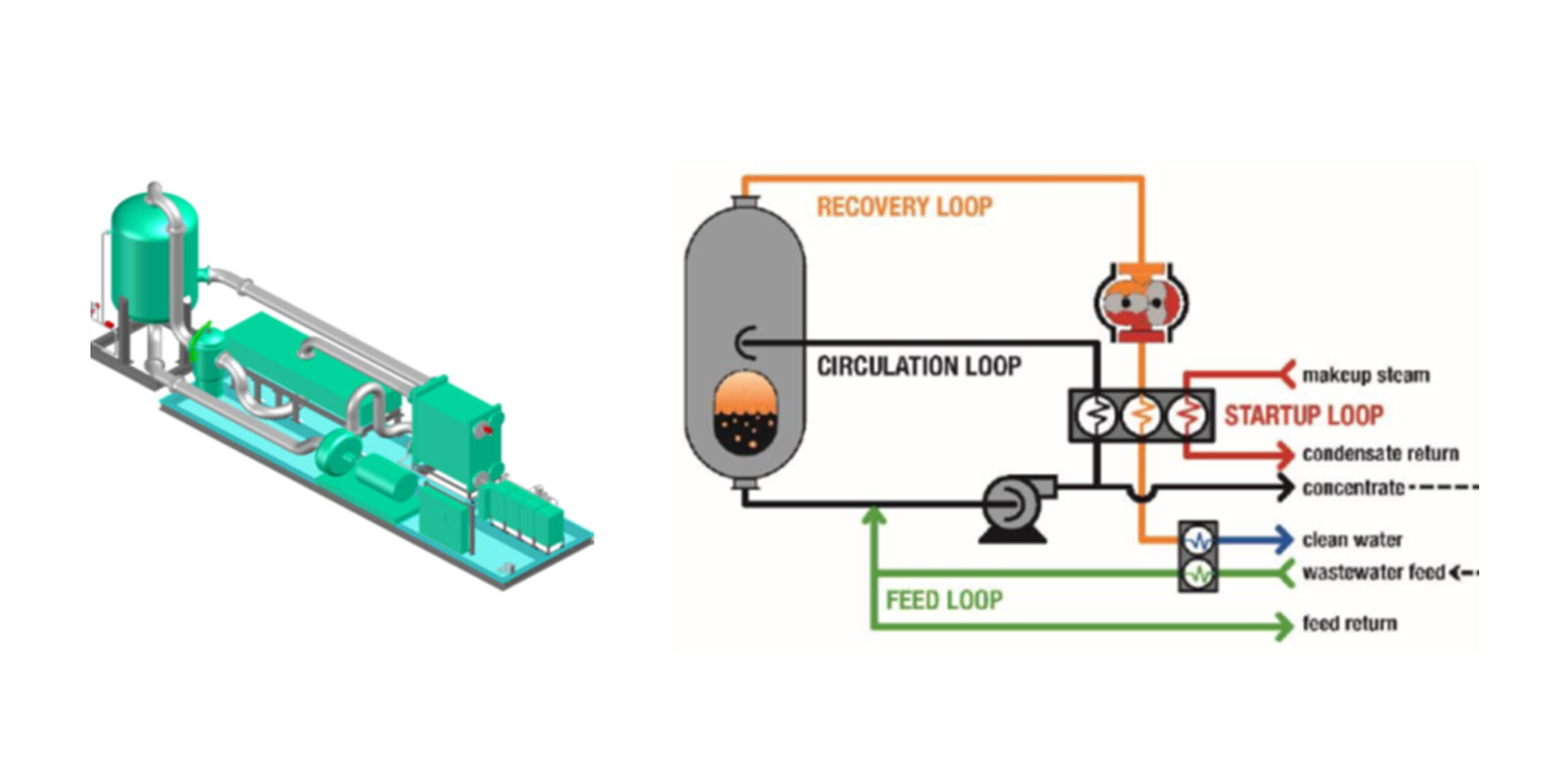

cEOR – Polymer Flooding

ClearBakk was approached by an Oil & Gas client in Alaska to design a polymer hydration package to extract more oil from their reservoir. We designed and built a 4.8 MT/day Chemical Enhanced Oil Recovery (cEOR) package in 5 months from initial purchase order (PO) to ready-to-ship in order to meet the client’s accelerated delivery schedule.

Evaluating Treatment Alternatives for Produced Water Treatment

ClearBakk conducted a technical assessment on treatment of produced water for storage in an open pond and reuse in fracking applications. Water analysis revealed challengingly high levels of TDS, oil content, TOC, and NORM contaminants. However, ClearBakk was able to provide both a cost-effective short-term solution and outline the final treatment requirements in a comprehensive report for the client.

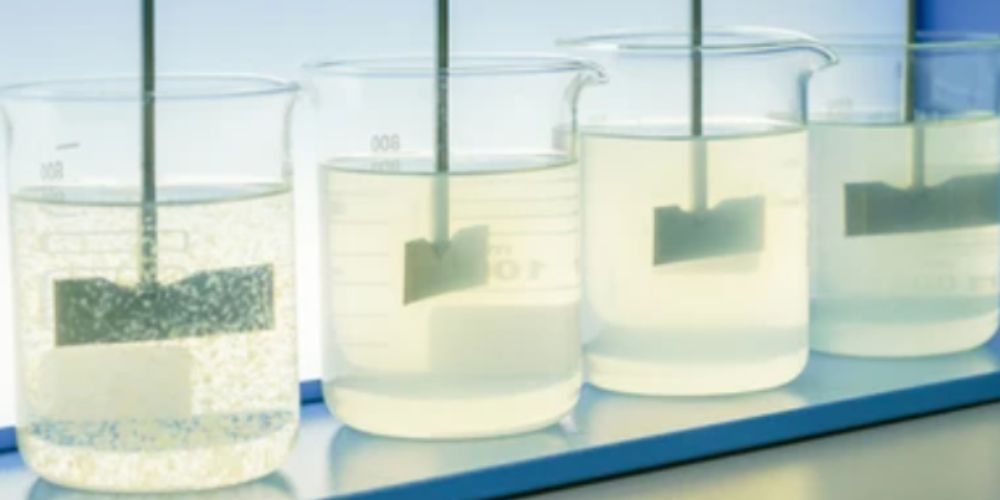

Treatment Feasibility Study

ClearBakk was approached by a major Oil & Gas client in Alberta, which required a solution aiming to treat its Frac Return Water and reclaim the water as a saleable product. Raw water was from different sources resulting in highly variable water quality. ClearBakk performed lab test to verify the treatment process to optimize the chemical dosing required to reclaim Fracking Return Water as a saleable product.

Mining Waste Water Nitrate Removal

A gold mining client in British Columbia was experiencing a wide range of flow rates of high nitrite waste water and needed a solution that was able to handle the wide range of flow rates and inconsistent high nitrite concentration without using chemicals / consumables.

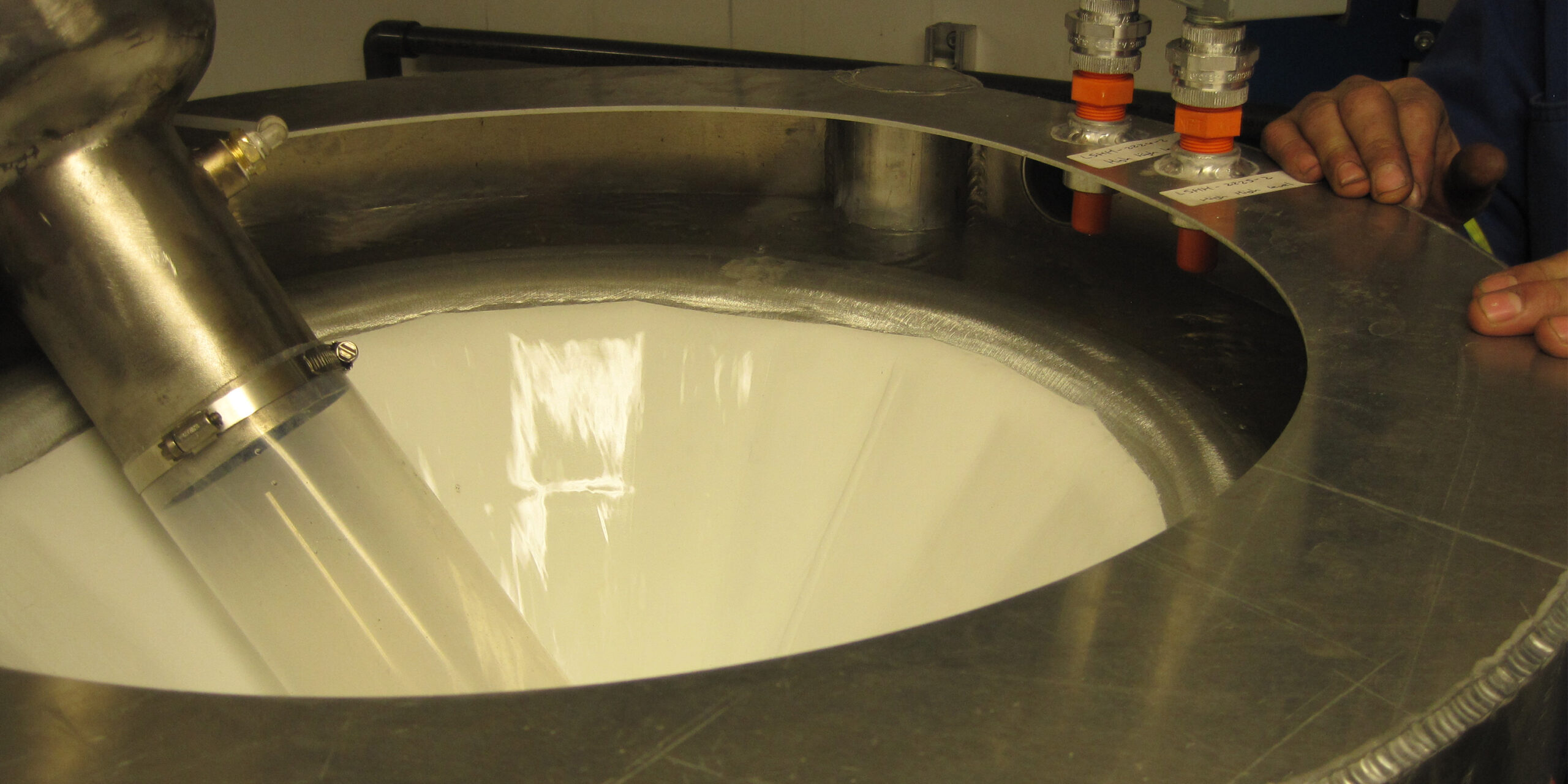

Modular Polymer Injection Pump Package

ClearBakk provided complete EPCM services for an Oil Sands client that needed a modular polymer injection pump package. The clients oil sands operation required a polymer solution injection package for an Atmospheric Fines Drying (AFD) trial that uses chemicals to help settle out solids in the fluid Fine Tailing (FFT) and composite tailings.